No products in the cart.

¿Por qué vaqueros posconsumo?

En 2018, 17 millones de toneladas de residuos textiles terminaron en vertederos.

Cada año, se producen aproximadamente 5.000 millones de vaqueros en todo el mundo.

Cada año se generan alrededor de 7,5 millones de toneladas de residuos textiles en Europa.

Menos del 1% de los residuos textiles se reciclan para producir prendas nuevas.

Hilos y tejidos eco-reciclados Infinit denim

El 95% de la ropa que se tira podría reciclarse o reutilizarse. Nuestra motivación por innovar nos ha llevado a diseñar y desarollar hilos y tejidos eco-reciclados que desafían los estándares de la sostenibilidad y circularidad en la industria textil.

Para crear estos hilos, combinamos restos de denim posconsumo de nuestras colecciones upcycled, con otras fibras celulósicas como Kapok, cáñamo o Lenzing refibra y/o fibras recicladas como algodón pre-consumo reciclado.

Lee más sobre los hilos y tejidos Infinit denim aquí.

¿Qué contienen nuestros hilos y tejidos?

Hilo kapok Infinit Denim

Tejido sarga plana Infinit Denim/

Tejido circular Infinit Denim

Tejido denim Infinit Denim

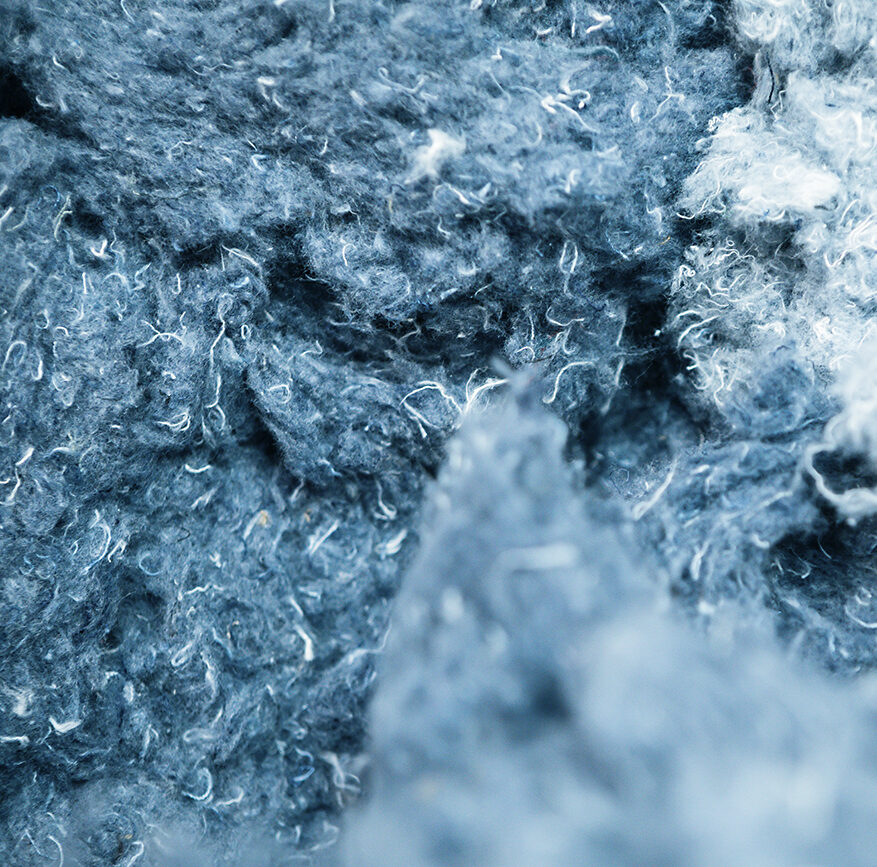

Fibras recicladas de vaqueros posconsumo

De nuestro proceso de Upcycling, se genera un subproducto que son retales de denim posconsumo que no se pueden reutilizar. A estos retales le extraemos las piezas metálicas y posteriormente son transportados a centros de triturado donde obtenemos nuevas fibras celulósicas. Estas fibras son mezcladas con otros materiales celulósicos para crear un nuevo hilo eco-reciclado. Finalmente, tejemos este hilo para crear nuevos tejidos.

Uno de los mayores beneficios de usar textiles posconsumo es que se minimiza al máximo la producción de nuevas fibras, ahorrando así el 100% de consumo de agua y de productos químicos. A su vez, alargando la vida de estos materiales impidiendo que vayan a un vertedero, y donde la descomposición de estas fibras contamina el agua y el suelo.

Las fibras de vaquero posconsumo se obtienen tras la trituración de los vaqueros pre-usados, depositados en los puntos de reciclaje textil del territorio español, y los restos sobrantes del proceso de fabricación upcycled.

Diseñamos todas nuestros hilos y tejidos con principios de diseño ecológico, materiales veganos, reciclados y/u orgánicos.

El cáñamo tiene fibras orgánicas 100% reciclables y biodegradables. La producción de cáñamo requiere mucha menos agua que, por ejemplo, la producción de algodón y suele requerir menos pesticidas. Además, almacena más CO2 del que emite. El cáñamos ayuda a combatir el cambio climático al atrapar el dióxido de carbono.

Las fibras de algodón preconsumo se obtienen a partir de la trituración de restos de tejidos de algodón. Estos restos se recogen durante el proceso de fabricación en múltiples fábricas de España especializadas en la producción de algodón (por ejemplo, camisetas y camisas).

A diferencia del algodón convencional, el algodón orgánico es cultivado con semillas naturales, sin emplear pesticidas ni químicos dañinos y asegurando condiciones laborales dignas. Su producción promueve y mejora la biodiversidad y los ciclos biológicos del algodón.

Las fibras TENCEL™ Lyocell se fabrican mediante la tecnología REBRIBRA™, que toma restos de algodón preconsumo y loz mezcla con pulpa de madera. Estas fibras se farican con al menos un 30% de material reciclado, procedente de residuos pre y postconsumo. Con el hilo REFRIBRA™ fabricamos tejidos suaves para ropa cómoda y prendas de punto circular. El Hilo de la refibra se ha utilizado para producir tejido en plana para prendas de verano más ligeras y para prendas creadas con tejido circular.

El kapok es una fibra celulósica natural, obtenida de un árbol cuyos frutos contienen fibras suaves, ligeras y sedosas, parecidas al algodón, pero que por su naturaleza no necesitan fertilizantes ni riego.

Pese a cultivarse lejos de España, es un material con mínima huella ambiental en su producción siendo imposible de equilibrar con otras fibras de cultivo más próximo. Además, el Kapok es un tipo de fibra celulósica facilitando su reciclado con algodón u Ecovero al final de su ciclo de vida.

El hilo Infinit denim de Kapok, es una mezcla de Kapok con denim posconsumo y que se ha utilizado en prendas que buscaban la suavidad y la ligereza como son las prendas de tricot.

LENZING™ ECOVERO™ se fabrica con madera certificada y obtenida de forma responsable. El proceso de producción utiliza menos productos químicos y menos agua. Está fabricado en Austria y más del 60% de los árboles utilizados para el tejido provienen de Alemania o Austria, reduciendo así las emisiones asociadas al transporte. Además, genera menos CO2 que otros tejidos. Cuando termina de usarse, se descompone de forma natural, lo que es estupendo para el medio ambiente.

El Ecovero es el componente básico de nuestro tejido sarga plana y con el que creamos todas las prendas grises y color de la colección.

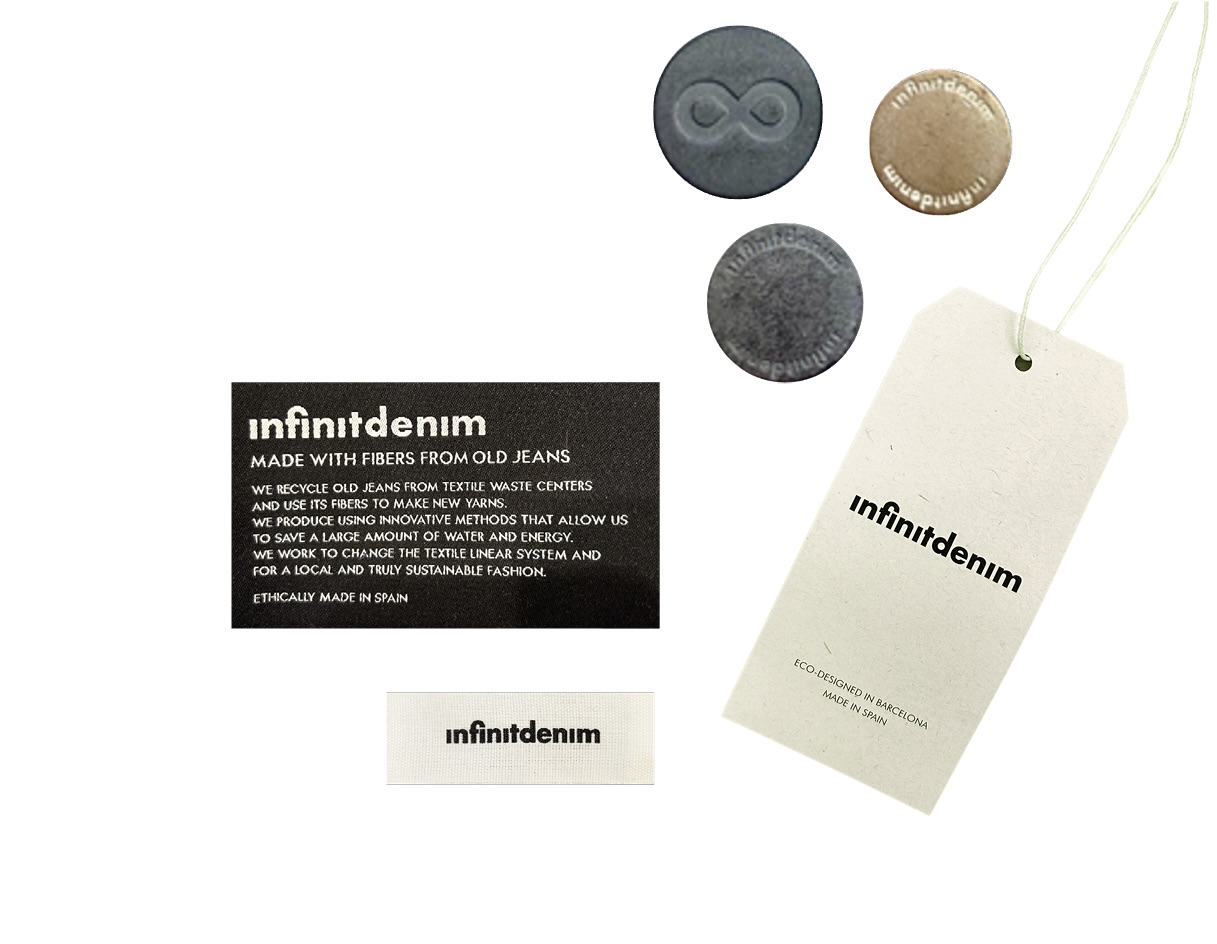

¿Qué contiene nuestra ropa?

Nuestros botones son de rosca para simplificar el reciclaje de la prenda y la reutilización de los botones. Están fabricados con ZAMAK reciclado. Esto ahorra residuos, energía y recursos al reducir la necesidad de extraer y procesar zinc, aluminio, magnesio y cobre.

Nuestras etiquetas están hechas de algodón, asegurando la monomaterialidad de las prendas y su reciclabilidad al fin de su vida útil.

Nuestras etiquetas de papel están hechas de papel reciclado. Para los pedidos y envíos en línea, utilizamos bolsas de plástico reciclado y sobres de papel.